AI Solutions for Manufacturing

Enhancing quality control, optimizing processes, and improving productivity with AI technology

Book a Consultation

In the rapidly evolving landscape of manufacturing, the integration of Artificial Intelligence and Industry Innovation (AI) consultancy services has become essential for enhancing operational efficiency and ensuring superior quality control. Our services are specifically designed for the manufacturing sector, focusing on how AI can optimize quality control processes, reduce defects, and improve overall productivity.

We provide tailored solutions that help manufacturers leverage advanced technologies such as machine learning, data analytics, and automation to overcome the numerous challenges they face, including rising competition, fluctuating market demands, and the need for continuous improvement in product quality.

Quality control is a critical component of the manufacturing process. It ensures that products meet specified standards and customer expectations. Effective quality control can lead to:

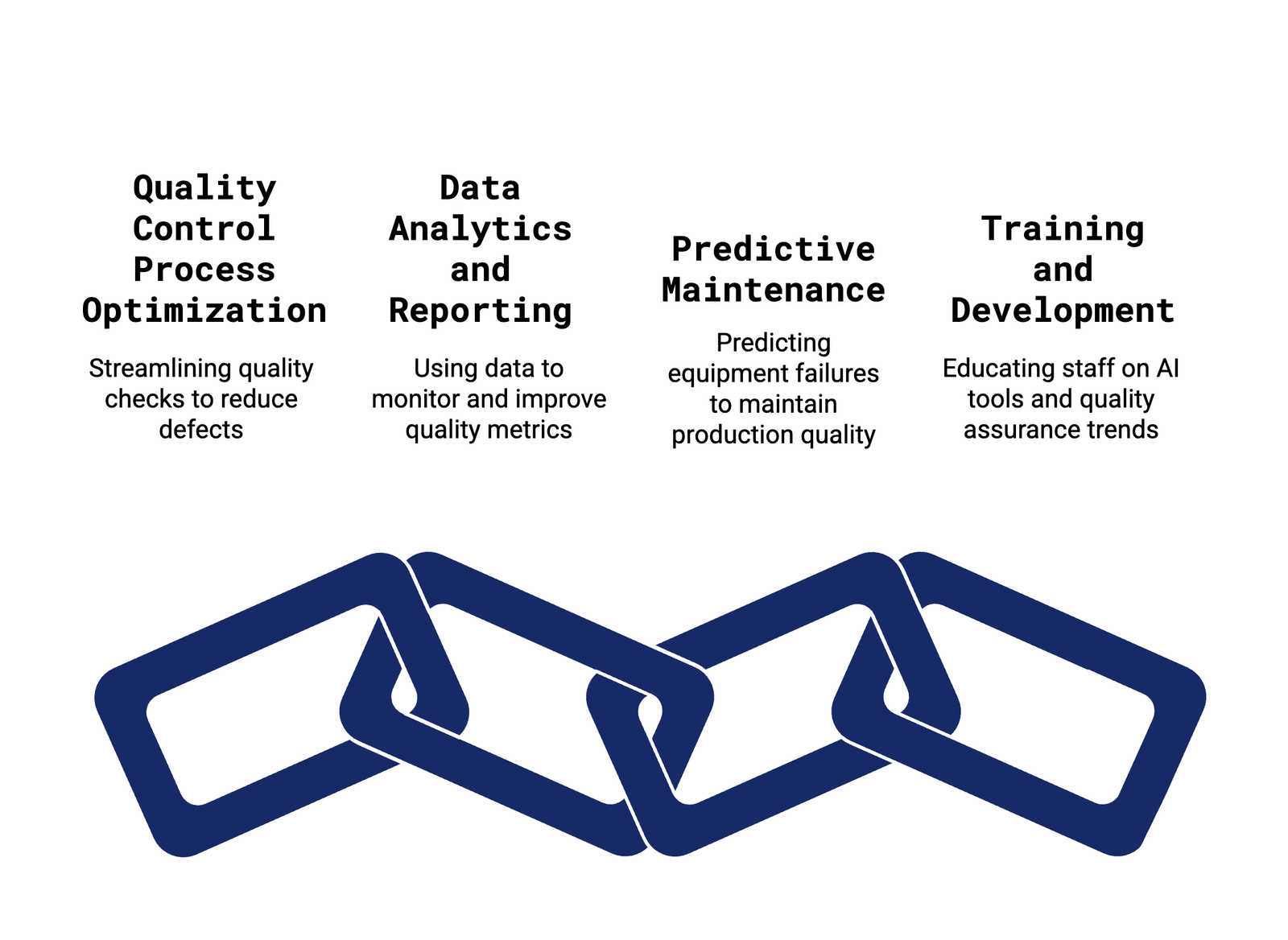

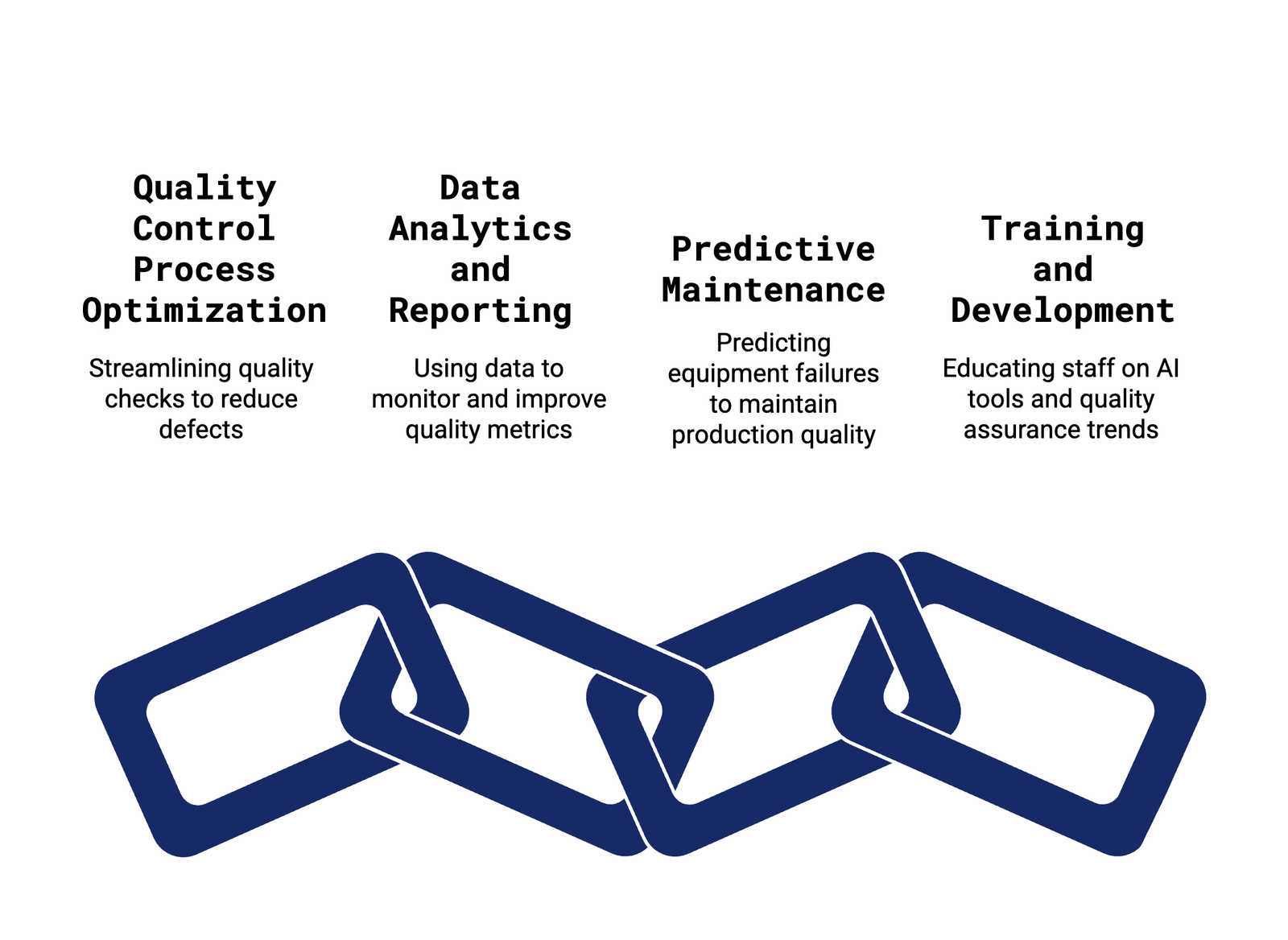

Streamlining quality checks to reduce defects. We analyze existing quality control processes and identify areas for improvement, implementing AI-driven inspection systems that utilize computer vision to detect defects in real-time and streamlining workflows to reduce bottlenecks and enhance efficiency.

Using data to monitor and improve quality metrics. Leveraging data analytics, we help manufacturers gather and analyze quality-related data, establishing key performance indicators (KPIs) to monitor quality metrics and creating dashboards for real-time reporting and decision-making.

Predicting equipment failures to maintain production quality. We implement predictive maintenance strategies that utilize AI algorithms to predict equipment failures before they occur, helping maintain production quality and reduce downtime with a proactive approach.

Educating staff on AI tools and quality assurance trends. To ensure the successful implementation of AI solutions, we provide training programs for staff, including workshops on the use of AI tools for quality control and continuous education on emerging trends in manufacturing quality assurance.

Our team of experts is ready to help you implement cutting-edge AI solutions tailored to your specific manufacturing needs. Schedule a consultation today to learn how we can help you enhance quality control, reduce costs, and improve productivity.

Book Your Consultation